Hammermills

Hammermills

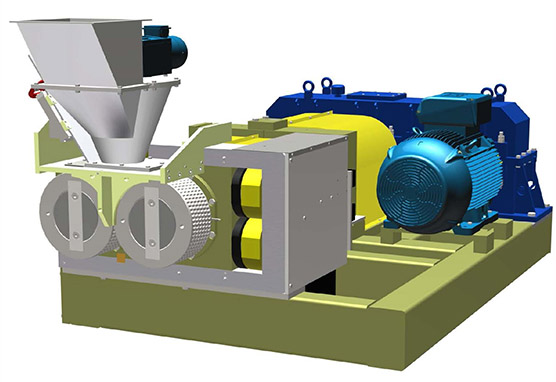

Sturtevant’s Hammermill provides excellent general size reduction for virtually any dry friable material. Sturtevant Hammermills are constructed from heavy-duty cast iron and are designed for the ultimate general size reduction of virtually any friable material. Materials are reduced to granular powder at a high rate through the use of swinging bar hammers. Product size is controlled be grates or screens. Capacities available from 1/2 ton to 6 tons per hour. Suitable for a wide variety of applications including chemicals, minerals and limestone.